Customized Size Nylon Plastic Track Wheels Pulley Small Wheels V Groove Belt Pulleys

As one of the manufacturers, suppliers, and exporters of plastic pulley Machinery Products, we offer plastic pulley and many other products. Please get in touch with us for details.

Customized Size Nylon Plastic Track Wheels Pulley Small Wheels V Groove Belt Pulleys

Customized Size Nylon Plastic Track Wheels Pulley Small Wheels V Groove Belt Pulleys are a type of pulley designed specifically for various applications. They are commonly used in machinery and equipment to guide and support the movement of belts or cables. These pulleys are made of high-quality nylon plastic material, which offers several advantages and unique features.

Features and Advantages

- Lightweight: The Customized Size Nylon Plastic Track Wheels Pulley Small Wheels V Groove Belt Pulleys are lightweight, making them easy to handle and install.

- Corrosion resistance: These pulleys have excellent resistance to corrosion, ensuring long-lasting performance even in harsh environments.

- Low friction: The pulleys have a low coefficient of friction, reducing wear and tear on the belts and cables, and improving overall efficiency.

- Electrical insulation: The nylon plastic material used in these pulleys provides excellent electrical insulation properties, making them suitable for applications where electrical conductivity must be avoided.

- Design flexibility: The pulleys offer design flexibility, allowing for easy customization and adaptation to various equipment and machinery.

- Noise reduction: The Customized Size Nylon Plastic Track Wheels Pulley Small Wheels V Groove Belt Pulleys are designed to minimize noise during operation, providing a quieter working environment.

Working Principle

The working principle of Customized Size Nylon Plastic Track Wheels Pulley Small Wheels V Groove Belt Pulleys involves the rotation of the pulley, which guides and supports the movement of the belt or cable. As the pulley rotates, it creates a smooth and consistent motion, allowing for efficient power transmission.

Applications

Customized Size Nylon Plastic Track Wheels Pulley Small Wheels V Groove Belt Pulleys have a wide range of applications across various industries. Some common applications include:

- Material handling equipment

- Conveyor systems

- Automotive industry

- Packaging machinery

- Textile machinery

What are Plastic Pulleys?

Plastic pulleys, such as Customized Size Nylon Plastic Track Wheels Pulley Small Wheels V Groove Belt Pulleys, are components used in machinery and equipment to guide and support the movement of belts or cables. They are made of high-quality nylon plastic material, which provides several advantages such as lightweight, corrosion resistance, low friction, electrical insulation, design flexibility, and noise reduction.

Working Principle of Plastic Pulleys

The working principle of Plastic Pulleys involves the rotation of the pulley, which guides and supports the movement of the belt or cable. As the pulley rotates, it creates a smooth and consistent motion, allowing for efficient power transmission.

Main Components of Plastic Pulleys

Plastic Pulleys, like Customized Size Nylon Plastic Track Wheels Pulley Small Wheels V Groove Belt Pulleys, consist of the following main components:

- Outer shell: The outer shell provides structural support and protects the internal components of the pulley.

- Groove or channel: The groove or channel is where the belt or cable is placed, ensuring proper alignment and smooth movement.

- Bearing or bushing: The bearing or bushing allows the pulley to rotate smoothly.

- Mounting mechanism: The mounting mechanism enables the pulley to be securely attached to the machinery or equipment.

Applications of Plastic Pulleys

Plastic Pulleys, including Customized Size Nylon Plastic Track Wheels Pulley Small Wheels V Groove Belt Pulleys, find applications in various industries, including:

- Material handling

- Conveyor systems

- Automotive

- Packaging

- Textile

- And many more

Factors to Consider When Choosing Plastic Pulleys

When choosing Plastic Pulleys, several factors should be taken into consideration:

- Load capacity: Ensure that the pulleys can handle the required load without compromising performance.

- Material compatibility: Consider the compatibility of the pulleys with the materials they will interact with.

- Environmental conditions: Assess the operating environment and choose pulleys that can withstand the specific conditions, such as temperature and humidity.

- Size and dimensions: Select pulleys with appropriate size and dimensions to fit the equipment and facilitate smooth movement.

- Installation and maintenance: Evaluate the ease of installation and maintenance requirements of the pulleys.

Differences Between Plastic Pulleys and Other Types of Pulleys

Plastic Pulleys, such as Customized Size Nylon Plastic Track Wheels Pulley Small Wheels V Groove Belt Pulleys, differ from other types of pulleys in several ways:

- Material: Plastic Pulleys are made of high-quality nylon plastic, while other pulleys may be made of metal or other materials.

- Weight: Plastic Pulleys are lightweight compared to metal pulleys, making them easier to handle and install.

- Corrosion resistance: Plastic Pulleys have excellent resistance to corrosion, unlike metal pulleys that may require additional protective coatings.

- Friction: Plastic Pulleys have a lower coefficient of friction, reducing wear on the belts or cables and improving efficiency.

Maintenance and Care Requirements for Plastic Pulleys

To ensure optimal performance and longevity of Plastic Pulleys, proper maintenance and care are essential:

- Regular cleaning: Remove dirt, debris, and lubricant buildup from the pulleys.

- Inspection: Check for any signs of wear, damage, or misalignment and address them promptly.

- Lubrication: Apply suitable lubricant as recommended by the manufacturer to maintain smooth rotation.

- Replacement: Replace any worn-out or damaged pulleys to prevent performance issues and potential equipment damage.

Trends in the Future Development of Plastic Pulleys

The future development of Plastic Pulleys is expected to focus on the following trends:

- Advanced materials: Continual advancements in materials technology will lead to the development of more durable and high-performance plastic pulleys.

- Enhanced design: Improved design techniques will result in pulleys with optimized performance and efficiency.

- Integration with IoT: Plastic Pulleys may become part of the Internet of Things (IoT) ecosystem, allowing for remote monitoring and control.

The Role of Plastic Pulleys in Environmental Protection and Sustainable Development

Plastic Pulleys contribute to environmental protection and sustainable development in several ways:

- Recyclability: Many plastic materials used in pulleys are recyclable, reducing waste and resource consumption.

- Energy efficiency: The low friction properties of plastic pulleys improve overall energy efficiency by reducing power losses.

- Longevity: Plastic pulleys are designed for durability, resulting in a longer lifespan and reduced need for frequent replacements.

- Reduced noise pollution: Plastic pulleys' noise reduction capabilities contribute to a quieter working environment.

Safety Precautions When Using Plastic Pulleys

When using Plastic Pulleys, it is important to follow these safety precautions:

- Ensure proper installation and secure attachment of the pulleys to prevent accidents or damage.

- Regularly inspect the pulleys for any signs of wear, damage, or misalignment that could compromise safety.

- Adhere to weight and load capacity limits to avoid overloading the pulleys.

- Wear appropriate protective gear, such as gloves and goggles, when handling or working near the pulleys.

Impact of New Materials and Technologies on Plastic Pulleys

New materials and technologies have a significant impact on Plastic Pulleys:

- Advanced polymers: The development of new polymer materials can enhance the performance and durability of plastic pulleys.

- 3D printing: Additive manufacturing techniques like 3D printing enable the production of complex pulley designs and customization.

- Sensor technology: Integration of sensors into plastic pulleys allows for real-time monitoring of performance and predictive maintenance.

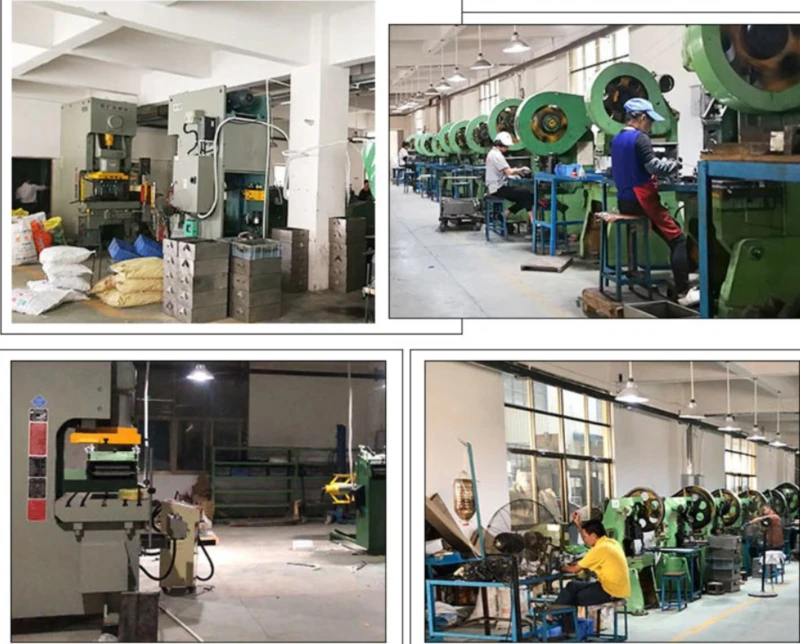

About Our Company

Our company is a leading player in the pulley market in China. We specialize in manufacturing a wide range of pulleys, including plastic pulleys, heavy-duty pulleys, gear pulleys, belt wheels, spinning pulleys, chain pulleys, compound pulleys, pulley pullers, belt pulleys, tensioner pulleys, spring pulleys, lifting pulleys, belt idler pulleys, timing pulleys, V pulleys, belt and pulleys, and more. With over 300 sets of automated CNC production equipment and fully automated assembly equipment, we ensure high-quality products and efficient production processes.

Product Promotion

At our company, we take pride in offering premium products, competitive prices, and excellent customer service. We welcome customers to provide us with their specific requirements for customized solutions. Our team is dedicated to delivering products that meet and exceed customer expectations.

Related Products

-

BS60832-12 8x32x12mm 608ZZ flat plastic roll with bearing for guide pulley rail

-

Customized Size Nylon Plastic Track Wheels Pulley Small Wheels V Groove Belt Pulleys

-

High Wear-Resistance Plastic Roller Wheels Small Pulley Belts Transmission Pulley

-

Kitchen food cabinet roller bearing BSR60519-7 5x19x7mm pom pulley wheel plastic nylon coated roller bearing for sliding door