Plastic Pulley

HIGH QUALITY PRECISE MANUFACTURER &SUPPLIER

Leading the plastic pulley industry: Innovative technology, professional services, and becoming an industry benchmark Plastic Pulley manufacturer

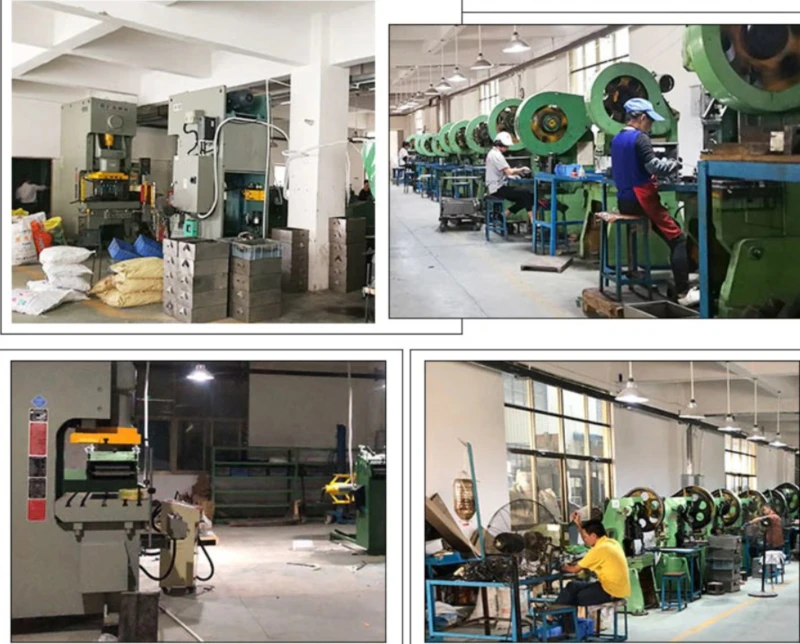

Founded over a decade ago, our company has emerged as a leading manufacturer and distributor of Plastic Pulleys, boasting a state-of-the-art facility and a dedicated team of engineers. With extensive industry experience and cutting-edge technology, we specialize in crafting innovative solutions tailored to the needs of diverse industries.

Our Plastic Pulleys stand out for their durability, lightweight design, corrosion resistance, and precision engineering, making them ideal for harsh environments and high-performance applications across automotive, machinery, and automation sectors. Our products significantly reduce maintenance costs and improve overall system efficiency.

As the industry pioneer, we have built a reputation for unparalleled expertise and influence in the Plastic Pulley landscape. Committed to excellence, we offer comprehensive service solutions, including prompt after-sales support and customized consultation. Our relentless pursuit of innovation ensures continuous product improvement and the delivery of cutting-edge solutions that keep our clients ahead of the curve.

The Difference Between Plastic Pulleys and Other Types of Pulleys

| Plastic Pulleys | Metal Pulleys | Nylon Pulleys | |

|---|---|---|---|

| Material | Made from plastic materials | Made from metals like steel, aluminum, or brass | Made from nylon, a synthetic polymer |

| Weight | Lighter than metal pulleys | Heavier than plastic pulleys | Lighter than metal pulleys, but heavier than some plastic types |

| Cost | Generally lower in cost compared to metal pulleys | Higher cost than plastic pulleys | Moderate cost, can be more expensive than some plastic types but less than metal |

| Durability | Can withstand moderate wear and tear | High durability, resistant to wear and tear | High durability, good resistance to wear and tear |

| Resistance to Corrosion | Lower resistance to corrosion and chemicals | High resistance to corrosion and chemicals | Moderate to high resistance to corrosion and chemicals |

| Temperature Resistance | Limited temperature range, may degrade at high or low temperatures | Wider temperature range, suitable for extreme conditions | Moderate temperature resistance, better than some plastics but less than metal |

| Noise | Tend to be quieter during operation | Can be noisy during operation, especially at high speeds | Moderate noise levels, often quieter than metal pulleys |

| Applications | Suitable for light-duty and non-corrosive environments | Ideal for heavy-duty applications and harsh environments | Widely used in various applications, balancing cost and durability |

| Maintenance | Lower maintenance requirements due to lower cost and light weight | Higher maintenance requirements in harsh environments due to wear and tear | Moderate maintenance, depending on the application |

What are Plastic Pulleys?

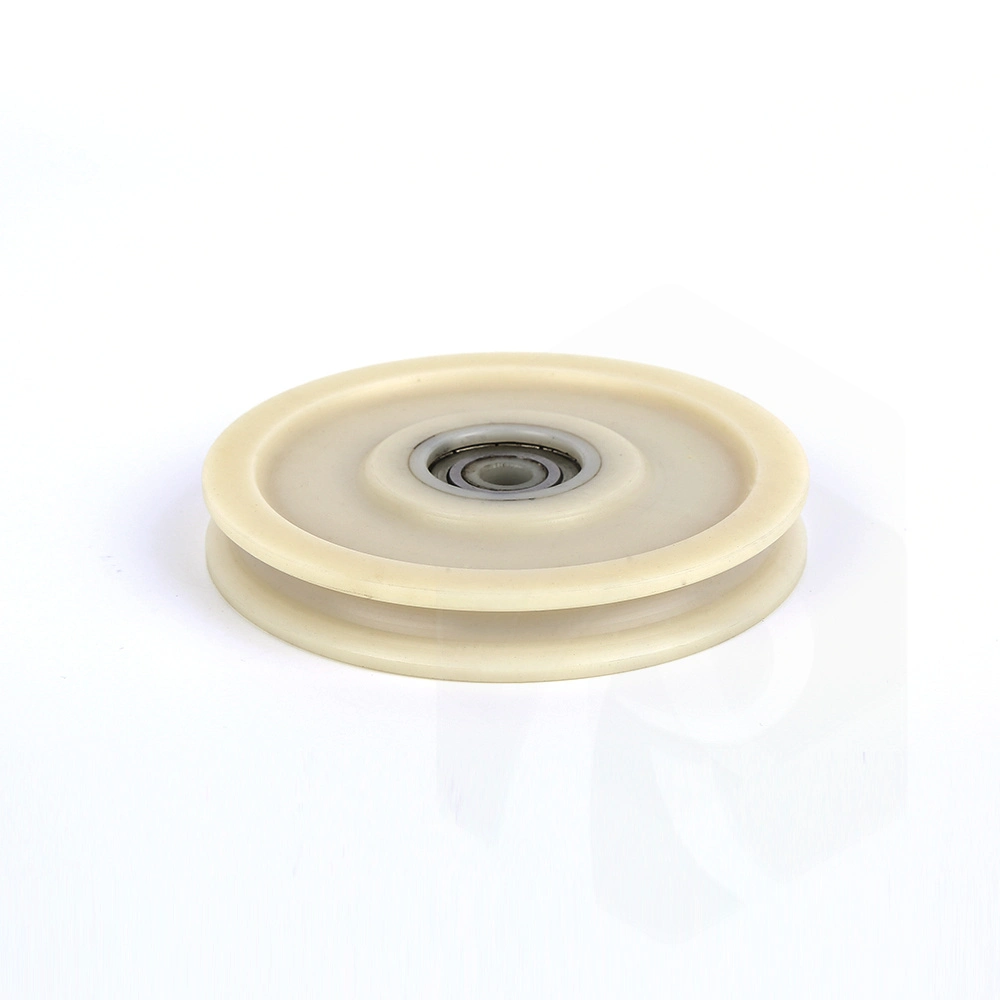

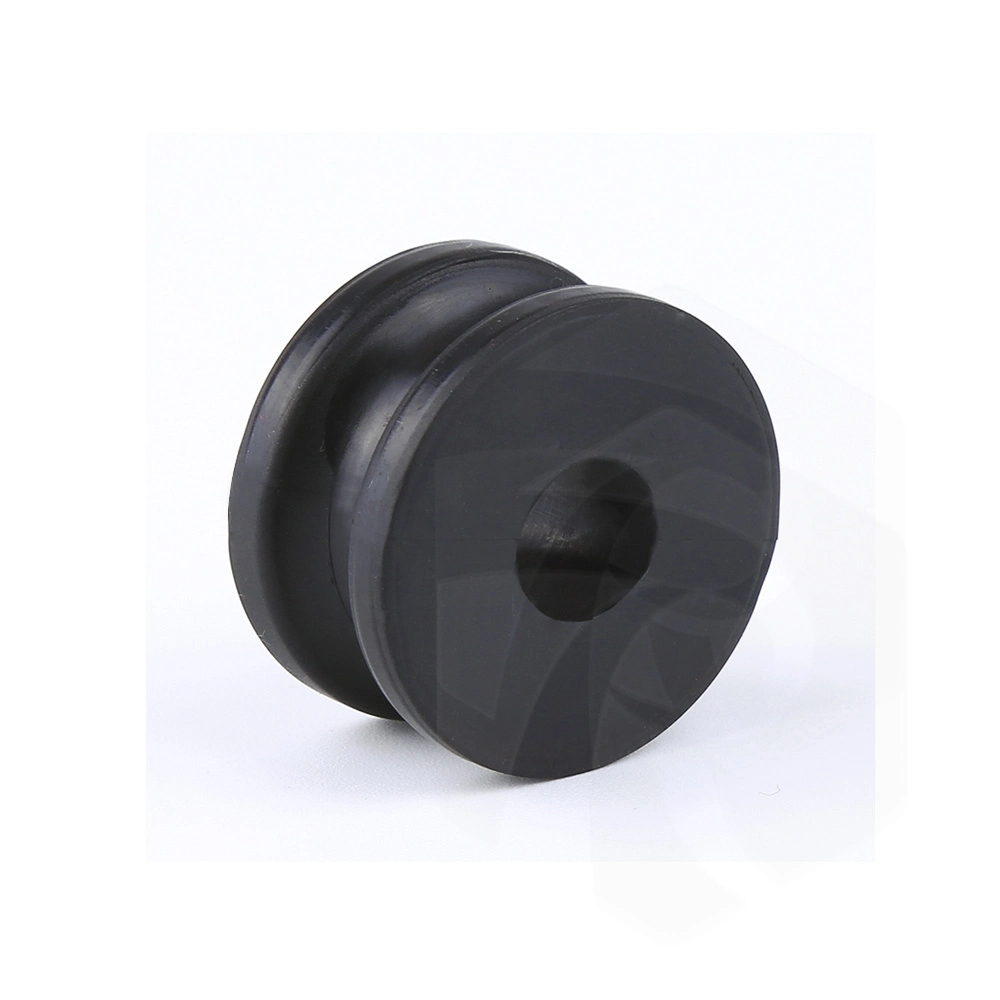

Plastic pulleys are mechanical components primarily made from various engineering plastics such as nylon, polyethylene, or polypropylene. They are designed with grooved rims or channels that guide and support cables, belts, or ropes to transmit motion or mechanical power. These pulleys are lightweight, resistant to corrosion, and offer low friction, making them suitable for a wide range of applications across industries.

Plastic pulleys are favored for their durability, affordability, and versatility in design. They are commonly used in machinery, automotive systems, home appliances, and industrial equipment where smooth and efficient movement of mechanical components is crucial. Their ability to resist wear and tear, dampen noise, and require minimal maintenance further enhances their appeal in various engineering applications.

Plastic Pulleys for sale

-

BS60832-12 8x32x12mm 608ZZ flat plastic roll with bearing for guide pulley rail

-

Customized Size Nylon Plastic Track Wheels Pulley Small Wheels V Groove Belt Pulleys

-

High Wear-Resistance Plastic Roller Wheels Small Pulley Belts Transmission Pulley

-

Kitchen food cabinet roller bearing BSR60519-7 5x19x7mm pom pulley wheel plastic nylon coated roller bearing for sliding door

-

Non-Standard Customized Conveyor Roller Nylon Rubber Polyurethane PU Bearing Plastic V Groove Drive Wheel Pulley for Industries

-

plastic sliding window roller wheel

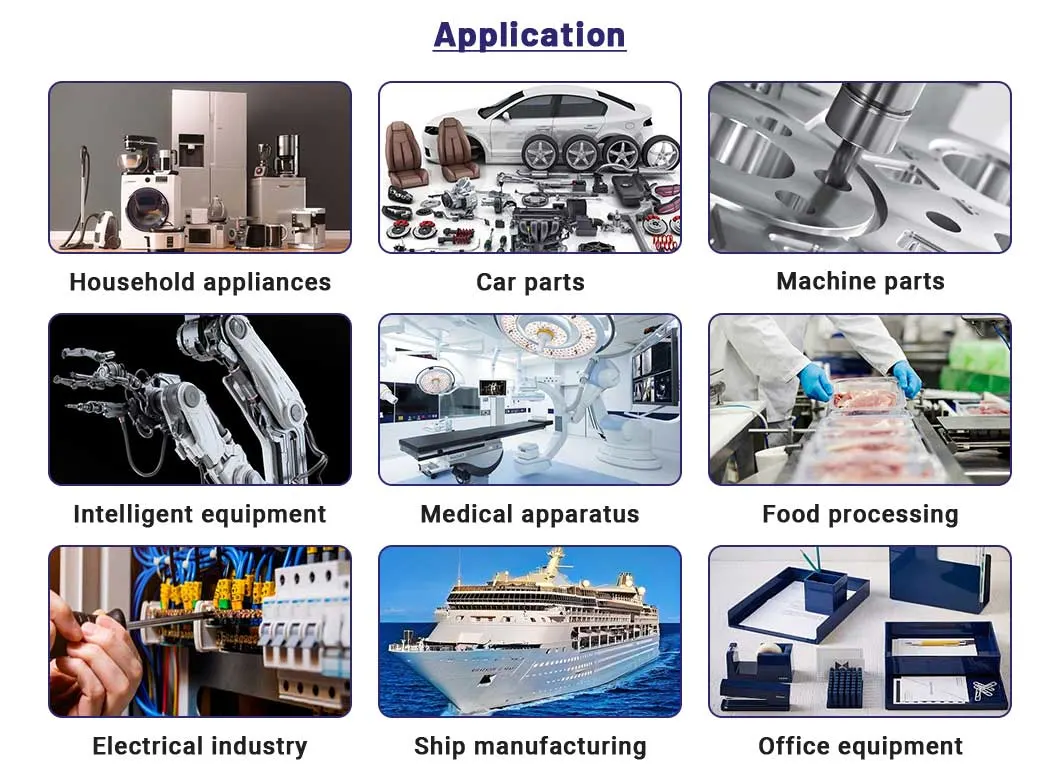

Application fields of Plastic Pulleys

Automotive Industry

Used in engine systems, timing belts, and HVAC systems for their lightweight nature and resistance to corrosion.

Industrial Machinery

Employed in conveyor systems, manufacturing equipment, and packaging machinery for low friction and durability.

Home Appliances

These are found in washing machines, dryers, and dishwashers to facilitate the movement of belts and cables with minimal noise.

Aerospace

Used in control systems and flight simulators for their lightweight properties and reliability.

Renewable Energy

Found in wind turbines and solar panel tracking systems to adjust positioning and movement with efficiency.

Medical Equipment

Utilized in medical devices and surgical instruments where sterilization and chemical resistance are critical.

Characteristics of Plastic Pulleys

Lightweight

Compared to metal alternatives, plastic pulleys are significantly lighter, making them easier to handle, transport, and install.

Corrosion Resistance

They are resistant to corrosion, making them ideal for outdoor and marine applications where exposure to moisture and harsh environments is common.

Low Friction

Many types of plastic used in pulleys offer low friction properties, reducing wear on belts, cables, or ropes and minimizing the need for lubrication.

Noise Reduction

Plastic pulleys operate quietly, making them suitable for applications where noise levels need to be minimized, such as in-home appliances or office equipment.

Design Flexibility

Plastic can be molded into complex shapes and configurations, allowing for customized pulley designs that meet specific application requirements.

Chemical Resistance

Certain plastics used in pulleys are resistant to chemicals, acids, and alkalis, enhancing their durability in environments with exposure to harsh substances.

The role of plastic pulleys in environmental protection and sustainable development

Recyclability: Many types of plastics used in pulleys are recyclable, which supports circular economy principles. Recycled plastic can be used to create new pulleys or other products, reducing the demand for virgin materials and minimizing waste.

Reduced Environmental Impact: Compared to metal pulleys, plastic pulleys generally have a lower environmental impact in terms of energy consumption and greenhouse gas emissions during production. They also require less maintenance and replacement, further reducing lifecycle environmental costs.

Resource Efficiency: Plastic pulleys are lightweight, which can lead to reduced transportation costs and fuel consumption during shipping. Their durability and resistance to corrosion can extend product lifetimes, reducing the need for frequent replacements and conserving resources.

Energy Efficiency: Due to their low friction properties, plastic pulleys contribute to energy efficiency in mechanical systems. They require less lubrication and operate with reduced frictional losses, which translates to lower energy consumption over time.

Versatility in Applications: Plastic pulleys are used in renewable energy systems like wind turbines and solar panels, where their lightweight and durable nature contributes to efficient energy generation. This application supports the shift towards cleaner energy sources and sustainability.

Innovative Materials: Advances in material science continue to improve the environmental performance of plastic pulleys. New bio-based plastics and recyclable composites offer alternatives that reduce environmental impact while maintaining performance and durability.

Regulatory Compliance: Plastic pulleys manufactured with eco-friendly materials and processes can help companies comply with increasingly stringent environmental regulations and standards.

The main components of Plastic Pulleys

Body: The main body of the pulley is typically made from durable engineering plastic such as nylon, polyethylene, or polypropylene. This component provides the structural integrity and shape necessary to guide and support cables, belts, or ropes.

Grooves or Channels: These are machined or molded into the outer surface of the pulley body. They are designed to accommodate and direct the movement of cables, belts, or ropes, ensuring smooth operation and minimizing wear.

Hub: The hub is the central part of the pulley where the shaft or axle is inserted. It connects the pulley to the rotating shaft or axle of the machine or system it is part of, allowing for rotational movement.

Bearings or Bushings: Some plastic pulleys incorporate bearings or bushings within the hub or around the shaft opening. These components reduce friction and allow the pulley to rotate smoothly on the shaft, enhancing efficiency and longevity.

Flanges: Flanges are raised edges or rims on the sides of the pulley body. They help to keep the cables, belts, or ropes aligned within the grooves during operation, preventing them from slipping off the pulley.

Fasteners: Depending on the design and application, plastic pulleys may include fasteners such as screws, bolts, or pins to secure the pulley to the shaft or axle and ensure it remains firmly in place during operation.

Optional Features: Depending on specific application requirements, plastic pulleys may include additional features such as reinforcement ribs for added strength, special coatings for enhanced durability or performance in specific environments, and custom designs to meet unique operational needs.

The main components of Plastic Pulleys

Maintenance and Care Requirements for Plastic Pulleys

Cleaning: Clean Plastic Pulleys regularly to remove accumulated dust, dirt, and grease. Use a mild detergent and a soft cloth; avoid strong acidic or alkaline detergents to prevent damage to the plastic surface.

Lubrication: Most Plastic Pulleys do not usually require regular lubrication due to their low friction characteristics. However, in some high-load or high-speed applications, you can consider using specially designed dry lubricants or greases to reduce friction and wear.

Inspection: Regularly check the condition of Plastic Pulleys, especially the degree of wear on their rims and grooves. If necessary, replace severely worn parts in time to prevent their affecting operational efficiency and safety.

Environmental protection: Plastic Pulleys generally have good resistance to general environmental conditions, but if they are exposed to extreme temperatures, UV exposure, or chemical corrosion for a long time, measures should be taken to protect or avoid direct exposure.

Avoid excessive load: To extend their service life and ensure safety, ensure that Plastic Propellers are used within their designed load range and avoid excessive load operation.

Periodic Overhaul: For Plastic Pulleys used frequently or in critical applications, it is recommended that they be regularly overhauled and maintained, including replacement of necessary parts and realignment of bearings or bushings.

Why choose our company?

1. High-quality products: Our company is committed to providing the highest-quality plastic pulley. Our products are precision-engineered and manufactured using advanced materials to ensure durability, reliability, and consistent performance.

2. Comprehensive Service: We pride ourselves on providing excellent customer service. Our professional team is ready to answer your questions, provide technical support, and provide solutions tailored to your needs.

3. Competitive Prices: Our company offers competitive prices without compromising quality. We believe in creating value for our customers and work hard to ensure our products fit every budget.

4. Excellent after-sales support: We know a product is only as good as the support you receive after purchasing it. Our company provides comprehensive after-sales services, including timely repair, replacement, and maintenance, ensuring that your plastic pulley is in optimal condition for a more extended period.

5. Rich product range: Our company provides a variety of plastic pulley shafts to meet different applications and requirements. We can provide you with the right product.