Non-Standard Customized Conveyor Roller Nylon Rubber Polyurethane PU Bearing Plastic V Groove Drive Wheel Pulley for Industries

As one of the manufacturers, suppliers, and exporters of plastic pulley Machinery Products, we offer plastic pulley and many other products. Please get in touch with us for details.

Non-Standard Customized Conveyor Roller Nylon Rubber Polyurethane PU Bearing Plastic V Groove Drive Wheel Pulley for Industries

The Non-Standard Customized Conveyor Roller Nylon Rubber Polyurethane PU Bearing Plastic V Groove Drive Wheel Pulley is a versatile product that is widely used in various industries. It is designed to provide efficient and reliable performance in conveyor systems.

Features and Benefits

- Lightweight: The plastic pulley is lightweight, making it easy to install and operate.

- Corrosion-resistant: The pulley is highly resistant to corrosion, ensuring its durability and longevity.

- Low friction: The plastic material of the pulley reduces friction, resulting in smooth and efficient operation.

- Electrical insulation: The pulley offers excellent electrical insulation properties, making it suitable for applications where electrical conductivity is a concern.

- Design flexibility: The plastic pulley can be easily customized to meet specific design requirements.

- Noise reduction: The pulley is designed to minimize noise, creating a quieter work environment.

The plastic pulley operates based on the principle of friction and rotation. It is designed to support and guide the movement of conveyor belts, allowing for efficient material handling.

The plastic pulley finds its applications in a wide range of industries, including manufacturing, logistics, packaging, and more. It is commonly used in conveyor systems, assembly lines, and production facilities.

What are Plastic Pulleys?

Plastic pulleys are mechanical devices that are used to support and guide conveyor belts in various industrial applications. They are made from high-quality plastic materials, which provide excellent performance and durability.

How do Plastic Pulleys Work?

Plastic pulleys work by rotating on an axle, supporting the movement of conveyor belts. The friction between the pulley and the belt allows for efficient material transportation.

Main Components of Plastic Pulleys

The main components of plastic pulleys include the plastic wheel, bearings, axle, and mounting brackets. These components work together to provide smooth and reliable operation.

Applications of Plastic Pulleys

Plastic pulleys are widely used in industries such as manufacturing, logistics, packaging, and more. They are commonly found in conveyor systems, assembly lines, and production facilities. Plastic pulleys are essential for efficient material handling and transportation.

Factors to Consider When Choosing Plastic Pulleys

When choosing plastic pulleys, it is important to consider factors such as load capacity, belt width, operating conditions, and environmental compatibility. These factors will ensure that the pulleys meet the specific requirements of the application.

Differences between Plastic Pulleys and Other Types of Pulleys

Compared to other types of pulleys, plastic pulleys offer unique advantages such as lightweight construction, corrosion resistance, low friction, and electrical insulation. These characteristics make them suitable for a wide range of applications.

Maintenance and Care for Plastic Pulleys

Proper maintenance and care are essential to ensure the optimal performance and longevity of plastic pulleys. Regular cleaning, lubrication, and inspection are recommended to keep the pulleys in good working condition.

Trends in the Future Development of Plastic Pulleys

As technology advances, plastic pulleys are expected to continue evolving. Future trends may include the use of advanced materials, improved designs, and enhanced performance to meet the ever-changing needs of industries.

Role of Plastic Pulleys in Environmental Protection and Sustainable Development

Plastic pulleys play a significant role in environmental protection and sustainable development. They offer benefits such as energy efficiency, reduced waste, and recyclability, contributing to a greener and more sustainable industrial sector.

Safety Precautions when Using Plastic Pulleys

When using plastic pulleys, it is important to follow safety guidelines and precautions. This includes proper installation, regular inspection, and adherence to recommended load capacities to ensure safe and reliable operation.

Impact of New Materials and Technologies on Plastic Pulleys

New materials and technologies have a profound impact on the development of plastic pulleys. Advancements in materials science and manufacturing processes lead to the introduction of innovative materials and designs, improving the performance and efficiency of plastic pulleys.

Company and Product Promotion

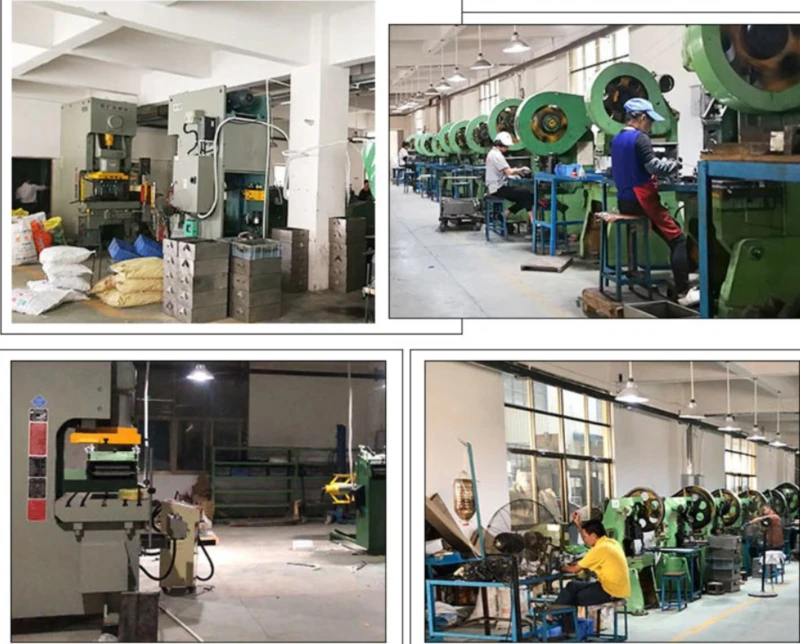

Our company is a leading player in the pulley market in China. We offer a wide range of products, including plastic pulleys, heavy-duty pulleys, gear pulleys, belt wheels, spinning pulleys, chain pulleys, compound pulleys, and more. With 300 sets of automated CNC production equipment and fully automated assembly lines, we ensure high-quality products and efficient production.

At our company, we pride ourselves on providing superior products, competitive prices, and excellent customer service. We welcome custom orders and guarantee customer satisfaction. Explore our extensive range of pulleys and experience the difference of our top-notch products.

Related Products

-

BS60832-12 8x32x12mm 608ZZ flat plastic roll with bearing for guide pulley rail

-

Customized Size Nylon Plastic Track Wheels Pulley Small Wheels V Groove Belt Pulleys

-

High Wear-Resistance Plastic Roller Wheels Small Pulley Belts Transmission Pulley

-

Kitchen food cabinet roller bearing BSR60519-7 5x19x7mm pom pulley wheel plastic nylon coated roller bearing for sliding door