Plastic Pulley for Launching – An In-depth Review

Introduction

Plastic pulleys have become an essential component in various industrial applications such as launching systems. Pulleys are used to reduce friction and to change the direction of a force, and plastic pulleys can withstand the high loads and stresses of these applications. In this article, we will delve into the use of plastic pulleys for launching systems.

Advantages of Plastic Pulleys for Launching

Plastic pulleys are preferred over other materials such as metal and wood because of several reasons:

- Lightweight

- Durable

- Resistant to corrosion and rust

- Low friction coefficient

Applications of Plastic Pulleys in Launching

Plastic pulleys are used in various launching systems such as:

- Sailing boats

- Zip lines

- Rocket launching mechanisms

- Glider launching mechanisms

Types of Plastic Pulleys for Launching

There are different types of plastic pulleys that are used in launching systems:

- Heavy Duty Pulleys – These pulleys are designed to withstand high loads and stresses.

- Gear Pulleys – These pulleys have teeth that mesh with other gears to transmit torque.

- Belt Wheels – These pulleys have a grooved outer surface that meshes with a belt to transmit power.

- Spinning Pulleys – These pulleys rotate around a stationary axle to change the direction of a force.

- Chain Pulleys – These pulleys have grooves that mesh with the links of a chain to transmit power.

- Compound Pulleys – These pulleys consist of multiple pulleys that work together to reduce the effort required to lift a load.

- Pulley Puller – These pulleys are used to remove pulleys from a shaft.

- Belt Pulley – These pulleys are used to transmit power between two shafts using a belt.

- Tensioner Pulley – These pulleys are used to maintain tension in a belt or chain.

- Spring Pulley – These pulleys use a spring to maintain tension in a belt or chain.

- Lifting Pulley – These pulleys are used in lifting systems to change the direction of a force.

- Belt Idler Pulley – These pulleys are used to guide a belt and maintain tension.

- Timing Pulley – These pulleys are used in timing belt systems to maintain synchronization between two shafts.

- V Pulley – These pulleys have a V-shaped groove that meshes with a belt to transmit power.

- Belt and Pulley – These pulleys are used together with a belt to transmit power between two shafts.

Features of Plastic Pulleys for Launching

To make plastic pulleys suitable for launching systems, they are designed with several features such as:

- High load-bearing capacity

- Low friction coefficient

- Corrosion and rust-resistant

- Lightweight and durable

- Can withstand extreme temperatures and pressures

- Can be customized to meet specific requirements

- Easy to install and maintain

Usage of Plastic Pulleys for Launching

Plastic pulleys are used in various launching systems such as sailing boats, zip lines, rocket launching mechanisms, and glider launching mechanisms. For example, plastic pulleys are used in sailing boats to hoist sails, in zip lines to transfer the weight of the user, in rocket launching mechanisms to guide the rocket, and in glider launching mechanisms to launch the glider.

Conclusion

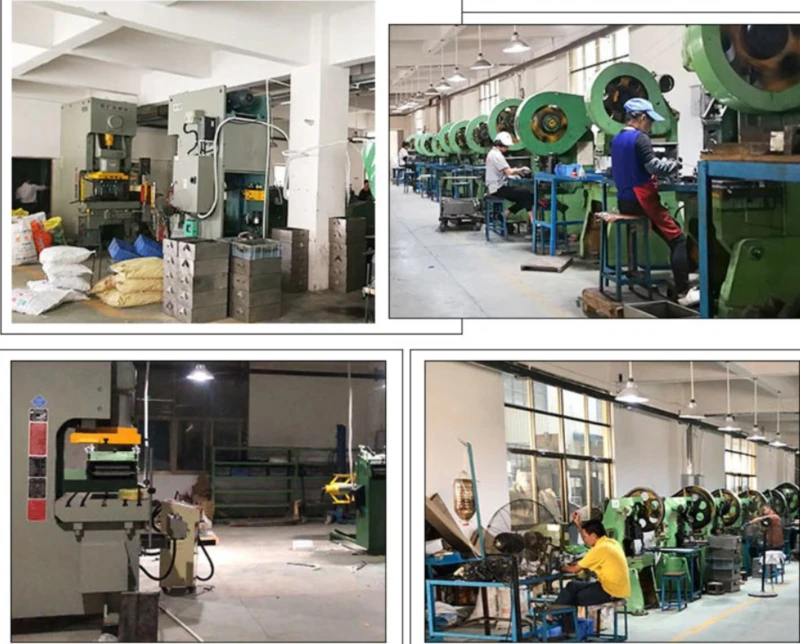

Plastic pulleys are essential for launching systems because of their durability, low friction, and high load-bearing capacity. There are different types of plastic pulleys that are used for various applications, and they can be customized to meet specific requirements. Our company specializes in manufacturing plastic pulleys and is the leading provider in the Chinese market. Our products include plastic pulleys, heavy-duty pulleys, gear pulleys, belt wheels, spinning pulleys, chain pulleys, compound pulleys, pulley pullers, belt pulleys, tensioner pulleys, spring pulleys, lifting pulleys, belt idler pulleys, timing pulleys, V pulleys, belt and pulley, and more. We have over 300 sets of fully automated CNC production equipment and automatic assembly equipment. We offer high-quality products, competitive prices, and excellent customer service. Please feel free to contact us for customized products.

Author: Czh