Plastic Pulley for Excavating

A plastic pulley is a type of pulley made from plastic materials. It is commonly used in excavating machinery due to its light weight and durability. In this article, we will discuss the advantages and disadvantages of using plastic pulleys for excavating, the different types of plastic pulleys available in the market, and how to choose the right plastic pulley for your excavating needs.

Advantages of Using Plastic Pulleys for Excavating

Plastic pulleys offer several advantages over their metal counterparts:

- Lightweight: Plastic pulleys are lighter than metal pulleys, which reduces the overall weight of the excavating machinery, making it more fuel-efficient and easier to maneuver.

- Durability: Plastic pulleys are highly durable and resistant to wear and tear, making them ideal for use in harsh working conditions.

- Corrosion-resistant: Plastic pulleys do not rust or corrode like metal pulleys, which means they have a longer lifespan and require less maintenance.

- Cost-effective: Plastic pulleys are generally cheaper than metal pulleys, which makes them a cost-effective option for those on a budget.

Disadvantages of Using Plastic Pulleys for Excavating

Despite their advantages, plastic pulleys also have some disadvantages:

- Lower load capacity: Plastic pulleys have a lower load capacity than metal pulleys, which means they are not suitable for heavy-duty applications.

- Lower temperature resistance: Plastic pulleys have a lower temperature resistance than metal pulleys, which means they may not be suitable for use in high-temperature environments.

- Less rigid: Plastic pulleys are less rigid than metal pulleys, which means they may deform or break under heavy loads or impacts.

Types of Plastic Pulleys

There are several types of plastic pulleys available in the market:

- Heavy Duty Pulley: Designed for heavy-duty applications, these pulleys have a higher load capacity than standard plastic pulleys.

- Gear Pulleys: These pulleys have teeth that mesh with the teeth of a gear, providing a positive drive for the machinery.

- Belt Wheels: These pulleys are designed to work with belts to provide power transmission.

- Spinning Pulley: These pulleys have a smooth surface that allows them to spin freely, reducing friction and wear.

- Chain Pulley: Designed for use with chains, these pulleys provide a positive drive for the machinery.

- Compound Pulley: These pulleys have multiple grooves that allow them to work with different belt sizes and types.

- Pulley Puller: Designed for removing pulleys from shafts, these tools make maintenance and repair easier.

- Belt Pulley: These pulleys work with belts to provide power transmission.

- Tensioner Pulley: These pulleys are used to maintain tension in the belts, preventing slippage and ensuring smooth operation.

- Spring Pulley: These pulleys have a spring mechanism that adjusts the tension in the belts automatically.

- Lifting Pulley: These pulleys are designed for lifting heavy loads, and they have a high load capacity.

- Belt Idler Pulley: These pulleys are used to guide and support the belts, reducing wear and extending their lifespan.

- Timing Pulley: These pulleys are designed to work with timing belts, providing accurate power transmission.

- V Pulley: These pulleys have a V-shaped groove that allows them to work with V-belts, providing better power transmission than flat belts.

Choosing the Right Plastic Pulley for Your Excavating Needs

When choosing a plastic pulley for your excavating needs, consider the following factors:

- Load capacity: Make sure the pulley you choose can handle the load you will be placing on it.

- Temperature resistance: Make sure the pulley can withstand the temperature conditions of your working environment.

- Belt size and type: Make sure the pulley is compatible with the size and type of belt you will be using.

- Shaft size: Make sure the pulley can fit properly on your machinery’s shaft.

By considering these factors, you can choose the right plastic pulley for your excavating needs.

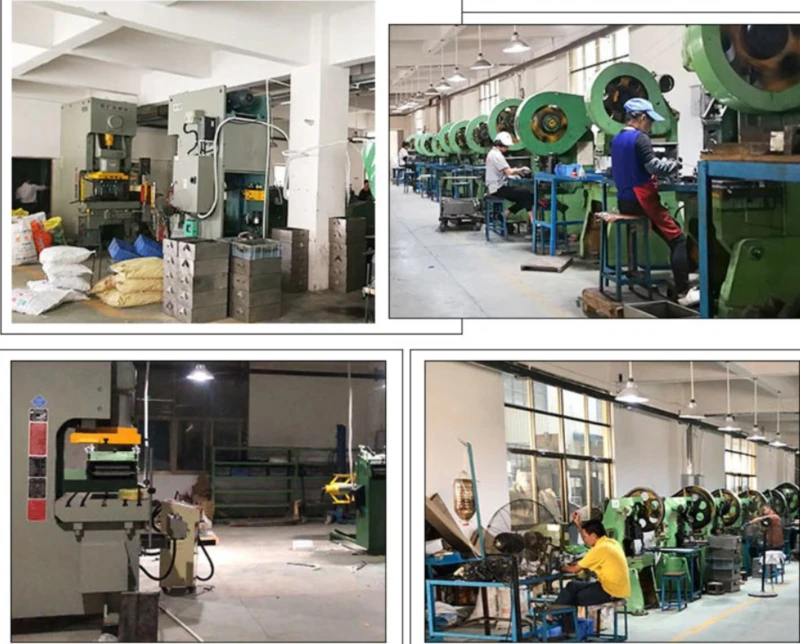

Company Introduction

Our company is a market leader in the pulley industry in China. We offer a wide range of products, including plastic pulleys, heavy-duty pulleys, gear pulleys, belt wheels, spinning pulleys, chain pulleys, compound pulleys, pulley pullers, belt pulleys, tensioner pulleys, spring pulleys, lifting pulleys, belt idler pulleys, timing pulleys, V pulleys, belt and pulley, and more. We have 300 sets of various automatic CNC production equipment and automatic assembly equipment.

Product Promotion

We pride ourselves on offering high-quality products, competitive prices, and excellent customer service. Our plastic pulleys are durable, lightweight, and corrosion-resistant, making them ideal for excavating machinery. We also offer customization services to meet the specific needs of our customers. Please visit our website or contact us for more information.

Welcome to our company. We look forward to working with you.

Author: Czh