Plastic Pulley for Drilling

Introduction:

Plastic pulleys are essential components in drilling machines. Their lightweight, durability, and resistance to corrosion make them ideal for use in various drilling applications. In this article, we will explore the different aspects of plastic pulleys for drilling and their significance in the industry.

1. Understanding Plastic Pulleys

Plastic pulleys are mechanical devices used to transmit power and motion between two rotating shafts. They consist of a plastic wheel with a groove for a belt or rope to run along. The plastic material used in these pulleys is carefully chosen to provide the required strength and reliability for drilling operations.

2. Advantages of Plastic Pulleys for Drilling

Plastic pulleys offer several advantages over traditional metal pulleys when it comes to drilling applications:

- Lightweight: Plastic pulleys are significantly lighter than their metal counterparts, reducing the overall weight and strain on drilling machines.

- Corrosion Resistance: Plastic pulleys are highly resistant to corrosion, making them suitable for use in humid or corrosive environments.

- No Lubrication Required: Unlike metal pulleys, plastic pulleys do not require regular lubrication, reducing maintenance time and costs.

- Noisy Operation: Plastic pulleys operate quietly, minimizing noise pollution in drilling operations.

3. Application Scenarios

Plastic pulleys find extensive use in various drilling scenarios, including:

- Construction Sites: Plastic pulleys are essential in construction projects, facilitating the movement of drilling equipment and ensuring smooth operation.

- Automotive Industry: Plastic pulleys are used in drilling machines for engine manufacturing, providing efficient power transmission.

- Woodworking: Plastic pulleys enable precise drilling in woodworking applications, allowing craftsmen to create intricate designs.

- Industrial Manufacturing: Plastic pulleys are utilized in large-scale manufacturing processes, ensuring reliable and efficient drilling operations.

4. Our Company’s Expertise in Plastic Pulleys

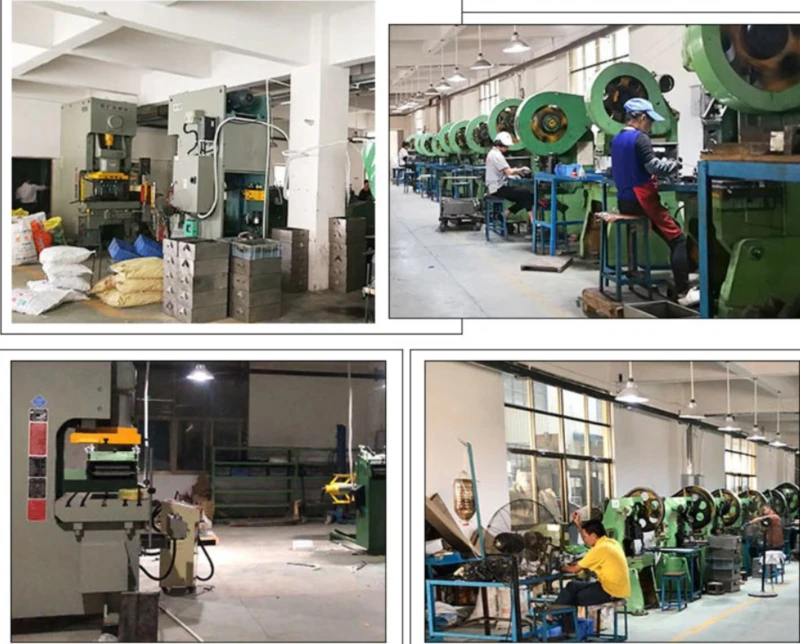

Our company is a leading player in the Chinese pulley market, specializing in the production of high-quality plastic pulleys for drilling. Our range of products includes plastic pulleys, heavy-duty pulleys, gear pulleys, belt wheels, spinning pulleys, chain pulleys, compound pulleys, pulley pullers, belt pulleys, tensioner pulleys, spring pulleys, lifting pulleys, belt idler pulleys, timing pulleys, V pulleys, belt and pulley setups, and more. With an extensive collection of 300 sets of fully automated CNC production equipment and assembly machinery, we ensure the precise manufacturing and assembly of our pulleys.

5. Promotion of Our Products

We take pride in offering top-quality products at competitive prices with exceptional customer service. Our plastic pulleys for drilling are meticulously designed and manufactured to meet the highest industry standards. Whether you require standard pulleys or customized solutions, we have the capability to fulfill your specific requirements. Customers are welcomed to provide their design specifications for personalized pulley solutions.

Author: Czh